CNC CNC grinder is mainly composed of bed, worktable, electromagnetic chuck, wheel box, sliding seat, column and other parts.

The CNC CNC grinder is a machine tool that uses a grinding wheel to grind the plane of various parts. The grinder is a more common type of surface grinder. It has high grinding accuracy and a smoother surface. It is easy to operate. It is suitable for grinding precision parts and various parts. For this kind of tools, the CNC CNC grinder has four motors, namely the grinding wheel motor, the grinding wheel lifting motor, the hydraulic pump motor and the cooling pump motor. The grinding wheel motor directly drives the grinding wheel to rotate and grinds the workpiece. In the surface grinder, the grinding wheel does not require speed adjustment, so it is usually driven by a cage asynchronous motor. This is the main movement of the surface grinder; the grinding wheel lift motor makes the grinding wheel Vertical movement is made on the column guide rail to adjust the position of the grinding wheel and the workpiece.

Cnc CNC grinding machine:

1. Grinding machine (numerical control tool) and tool grinding and cutting technology.

2. The first large-scale CNC precision vertical grinder passed the appraisal in Tianjin.

3. Undertake the preparatory work of the national grinding machine tool working group.

4. The CNC roll grinder was born in Shanghai and passed the user's pre-acceptance.

5. Large-scale CNC ball valve grinder produced is the best in China.

The reciprocating movement of the worktable and the grinding wheel is hydraulically driven by the hydraulic pump motor. The hydraulic transmission is relatively stable and can realize stepless speed regulation. The inertia during commutation is small and the commutation is stable. The reciprocating movement of the surface grinder table adopts hydraulic transmission, which can ensure the machining accuracy. The hydraulic pump is driven by the hydraulic motor, and the reciprocating movement of the worktable is realized by the hydraulic transmission device. The cooling pump motor drives the cooling pump to supply the grinding wheel and the workpiece cooling liquid, and at the same time, the cooling liquid is used to take away the ground iron filings.

Analyze the causes of common failures of surface grinders, summarize typical failure types and repair solutions, and introduce the maintenance strategies of grinders, which have certain reference and reference value for the use, repair and maintenance of surface grinders.

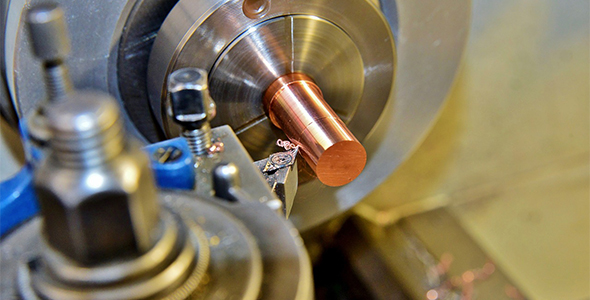

Typical process of processed products

(1) The machining of the chip flutes of ordinary grinding end mills adjust the relative position of the grinding wheel and the workpiece through the movement of the X, Y, and Z axes; when grinding the chip flutes, the A axis rotates and the U axis feeds linearly to complete the chip flute. Chip flute machining.

(2) Machining of taper end mill chip flute Taper end mill chip flute requires equal pitch and equal rake angle to ensure the same cutting performance at each outer circle of the end mill. Ordinary machine tools can only process equal-lead chip pockets, but cannot process equal-pitch, equal-rake-angle chip pockets, and continuous trial grinding is required during machining to obtain a more ideal geometry. The machining process of CNC tool grinder is:

Adjust the relative position of the grinding wheel and the workpiece through the movement of X, Y, Z axis; when grinding the chip flute, the A axis rotates, the U axis feeds linearly, and the Z axis moves from top to bottom to complete the chip flute machining.

(3) Machining of chip pockets of ball-end milling cutters. The chip pockets of ball-end milling cutters are required to be spiral flutes with the cutting edge over the center to ensure smooth cutting and convenient chip removal. The machining process of the CNC tool grinder is: adjust the relative position of the grinding wheel and the workpiece through the movement of the X, Y, and Z axes; when grinding the chip flute, the A axis rotates, the U axis linear feeds, and the W axis rotates to complete the chip flute processing. .

(4) The cnc numerical control grinder of the peripheral tooth clearance angle, end tooth rake angle, end tooth clearance angle and chisel edge of milling cutters, drills and reamers can change the grinding wheel clamped on the spindle, and the workpiece can be clamped at a time. Complete the processing of chip flutes, rake angle, relief angle, chisel edge and other processes.

WeChat scan code

WeChat scan code

support hotline189-1267-9267

mobile phone189-1267-9267

Copyright © 2022 Kunshan Jimda Precision Machinery Co., Ltd. All Rights Reserved. Add:No. 28, Zhisheng Road, Chengbei, Yushan Town, Kunshan City, Jiangsu Province